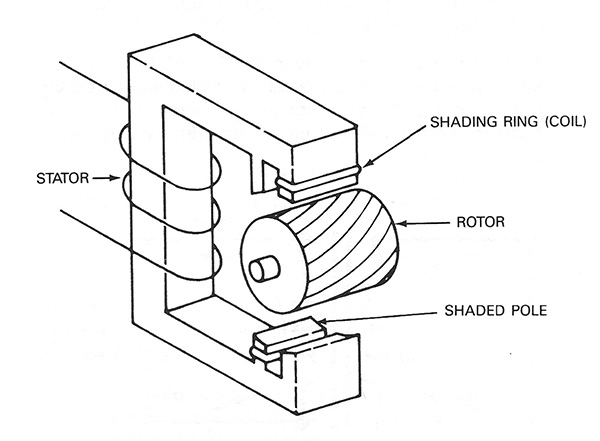

Split phase motors are a single-phase AC induction motor that features a main winding and a start winding that provides additional torque during startup. Their high efficiency, quietness, and compact size make them ideal for modern, high-tech air conditioning systems for homes and offices, providing exceptional performance while easily meeting energy efficiency regulations and guidelines. This technology enables them to maintain consistent speed in varying load conditions and reduces inefficiencies typically found in brushed commutation.Īlthough ECM motors are relatively expensive, they offer many advantages, including significant torque characteristics over the entire speed range and easier speed control capability. Typically operating on AC power, they use a built-in inverter to convert the power to DC and feature a microprocessor that manages commutation, removing the need for brushes that can wear out over time. ECM MotorsĮCM motors (Electronically Commutated Motors), also known as brushless DC motors, offer standout performance characteristics compared to virtually every other electric motor type. This makes them easily the most common motors in HVAC systems, used for fans, pumps, and compressors in small to medium applications. PSC motors are cost-effective, versatile motors without being exceptional in any area, with outstanding reliability due to avoiding the necessity for a centrifugal switch that can wear out over time. Where energy efficiency is a primary concern, PSC motors are being displaced by ECM motors in many new products and installations. Having both windings connected simultaneously provides an approximation of two-phase operation, which contributes to smoother, more efficient running and higher overall torque than a single-phase motor can typically provide. The capacitor gives the motor moderate additional torque during startup and while running.

#Emc motors wiring diagram hvac series#

They are characterized by having both a main winding and an auxiliary winding (the latter connected in series with a capacitor) permanently engaged in the motor circuit.

PSC (Permanent Split Capacitor) motors are a type of AC single-phase induction motor with mid-level characteristics that make them capable of handling many different tasks. Let's take a look at each of them in turn and cover the basics of how they work and how they compare with each other. In the field, you'll find the following motor types operating in HVAC systems. Energy efficiency, reliability, and cost are also important factors, and each motor type comes with its own set of strengths and limitations. Blower HVAC motors driving fans have low starting torque requirements, while the compressor and pump motors require higher starting torque. The type of motor used in an HVAC system depends on the application. They can range in size from small motors in domestic appliances such as fridges and air conditioners to large motors operating industrial furnaces.

Within these systems, electric motors perform critical duties operating fans, pumps, and compressors. HVAC (Heating/Ventilation/Air-Conditioning) systems manage the heating, cooling, and circulation of air between indoor and outdoor environments in residential, commercial or industrial settings. To perform repairs as quickly and efficiently as possible, develop an understanding of common types of HVAC motors and how they work. When repairing and maintaining equipment, service technicians will encounter a variety of motors performing different tasks. Electric motors are integral to HVAC systems, moving hot and cold air, pumping water, and operating compressors.

0 kommentar(er)

0 kommentar(er)